In modern industrial automation, reliable communication between remote I/O and PLCs is essential. The Schneider Electric CRA module enables efficient Ethernet-based remote I/O connectivity in PLC and DCS systems, improving scalability, diagnostics, and overall networked automation performance.

Product Details

Overview

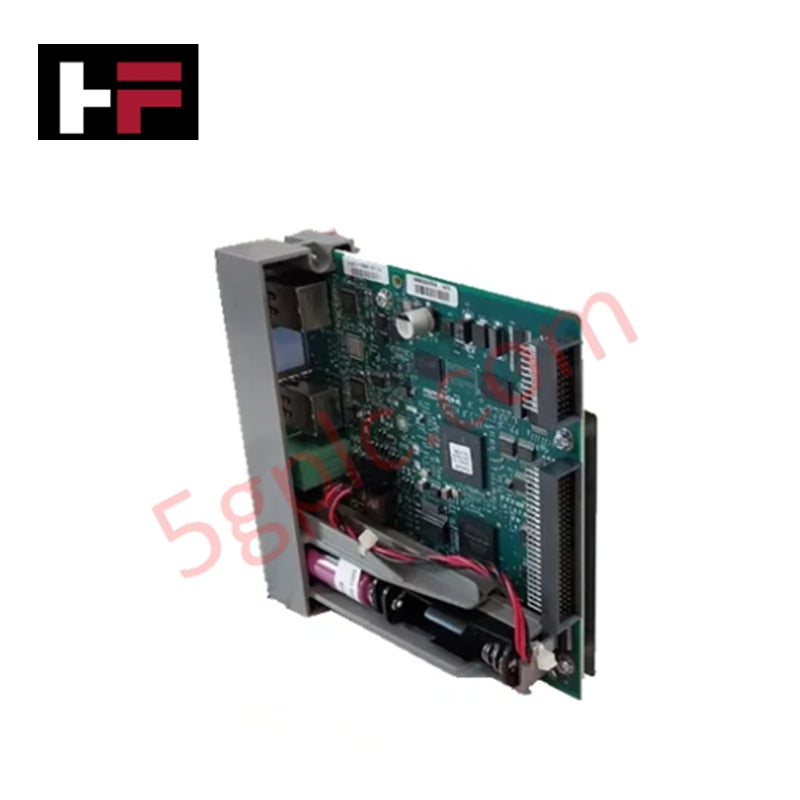

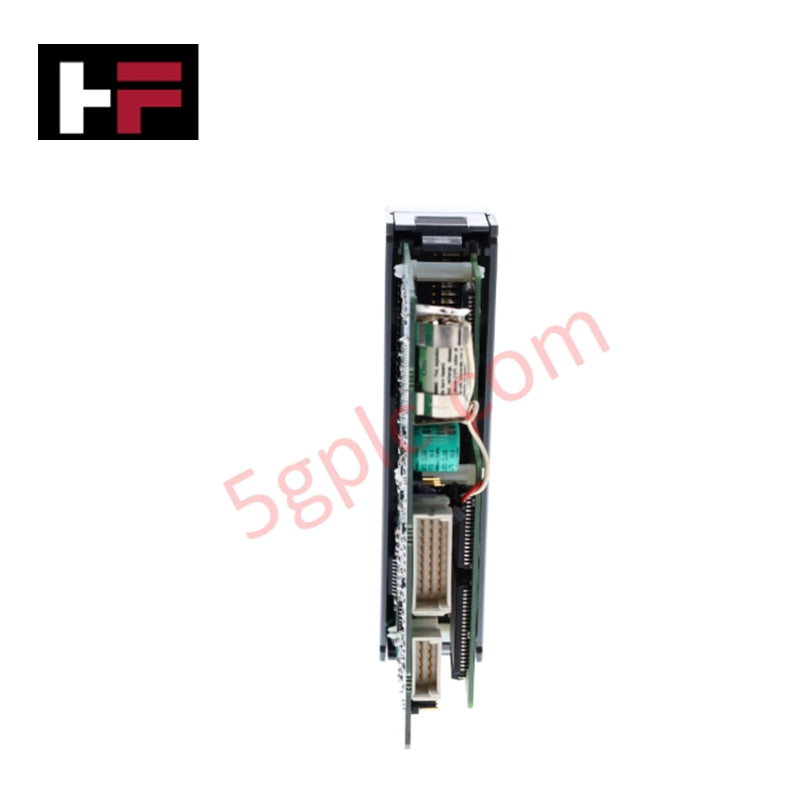

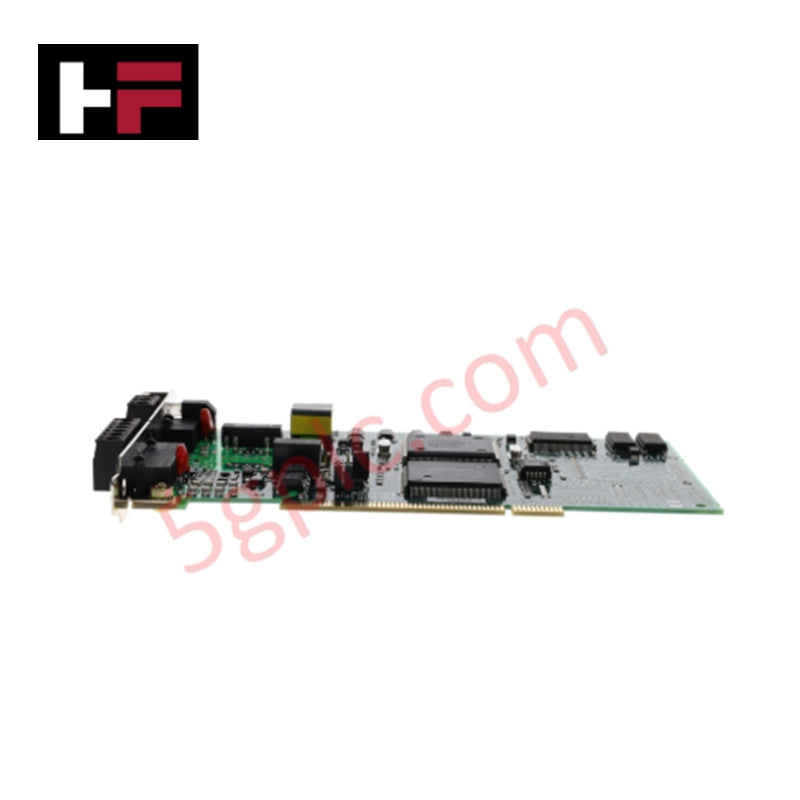

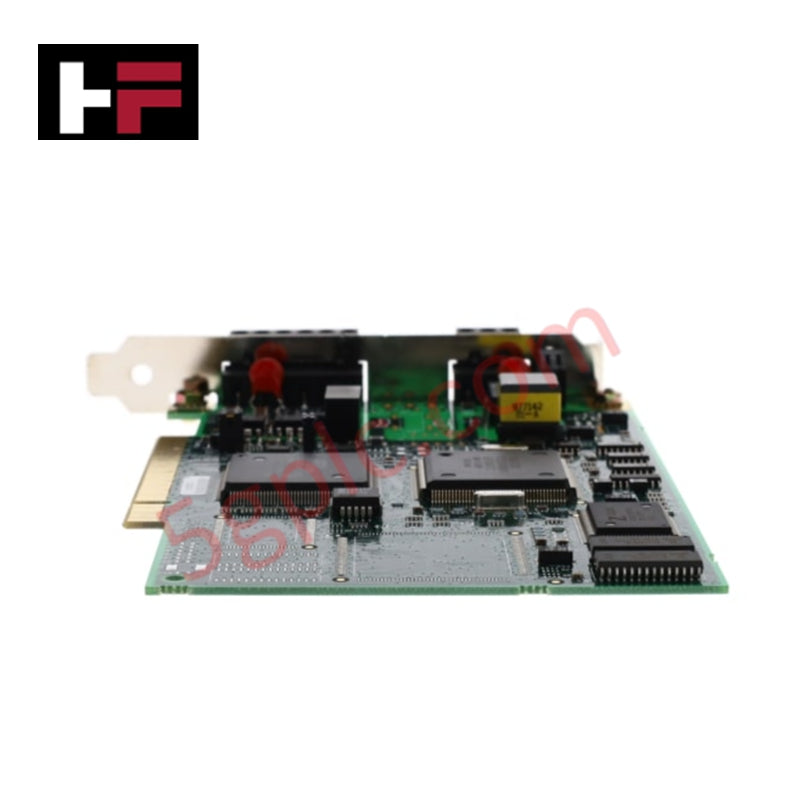

The Honeywell 900C30S-0360-00 is a C30 Controller CPU engineered for the ControlEdge HC900 hybrid control system. Designed with a modular, metal-enclosed architecture, this controller combines robust computational performance with flexible I/O configuration. It supports up to 400 function blocks and multiple analog and digital I/O points, making it a versatile solution for process control, data acquisition, and automation tasks across industrial environments.

Technical Specifications

-

Model Number: 900C30S-0360-00

-

Manufacturer: Honeywell

-

Product Type: C30 Controller CPU

-

Series: ControlEdge HC900

-

Controller Design: Modular metal rack enclosure supporting power supply, CPU, and user-selectable I/O modules

-

Analog Inputs:

-

Universal: Up to 96 channels

-

High-level: Up to 192 channels

-

Analog Outputs:

-

Standard Outputs: 40 channels

-

External Power Outputs: Up to 192 channels

-

Digital Inputs/Outputs: 384 channels total

-

Function Blocks: 400 per controller (supports complex control logic and PID loops)

-

Controller I/O Support: Compatible with racks offering 4, 8, or 12 I/O slots

-

Mounting Method: Surface-mount installation with 4 rear mounting screws

-

Installation Standards:

-

Installation Category II

-

Pollution Degree 2

-

IEC 664 and UL840 coordination compliance

-

Power Supply: 24 VDC nominal

-

Cooling Method: Natural convection (no fan required)

-

Operating Temperature: –40°C to +70°C (–40°F to +158°F)

-

Storage Temperature: –40°C to +85°C (–40°F to +185°F)

-

Humidity Range: 5%–95% RH, non-condensing

-

Material: Rugged aluminum rack with EMI shielding

Key Features

-

High Performance Control: Supports up to 400 control and computation function blocks.

-

Flexible I/O Configuration: Compatible with multiple rack sizes (4, 8, or 12-slot) for scalable system design.

-

Comprehensive Signal Support: Manages up to 192 analog inputs and 384 digital I/O points.

-

Robust Construction: Metal chassis with industrial-grade durability for harsh plant environments.

-

Modular Design: Simplifies maintenance and expansion for customized system architecture.

-

Installation Flexibility: Compact surface-mount design compliant with IEC and UL standards.

-

Reliable Power & Operation: 24 VDC operation with passive cooling ensures long-term stability.

Application Scenarios

-

Distributed control systems (DCS) and process automation in manufacturing plants.

-

Data acquisition and control in oil & gas, chemical, and power industries.

-

Continuous process applications requiring large-scale analog and digital I/O management.

-

Modernization or upgrade projects within Honeywell HC900-based control architectures.

FAQs

-

Q1: What is the main role of the 900C30S-0360-00 CPU?

It serves as the primary control processor in the HC900 system, handling computation, logic execution, and I/O management. -

Q2: Can it support redundant configurations?

While the C30 itself is a single CPU module, redundancy is supported through paired rack and control designs. -

Q3: How many function blocks can it process?

It supports up to 400 function blocks, suitable for complex control strategies. -

Q4: What installation standards does it comply with?

It meets IEC 664 and UL840 standards for industrial safety and reliability. -

Q5: Is it compatible with both 8-slot and 12-slot racks?

Yes, the C30 controller can be installed in racks with 4, 8, or 12 slots.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.

Tech & Buying Guide

Technical Insights, Installation Guides, and Buying Tips