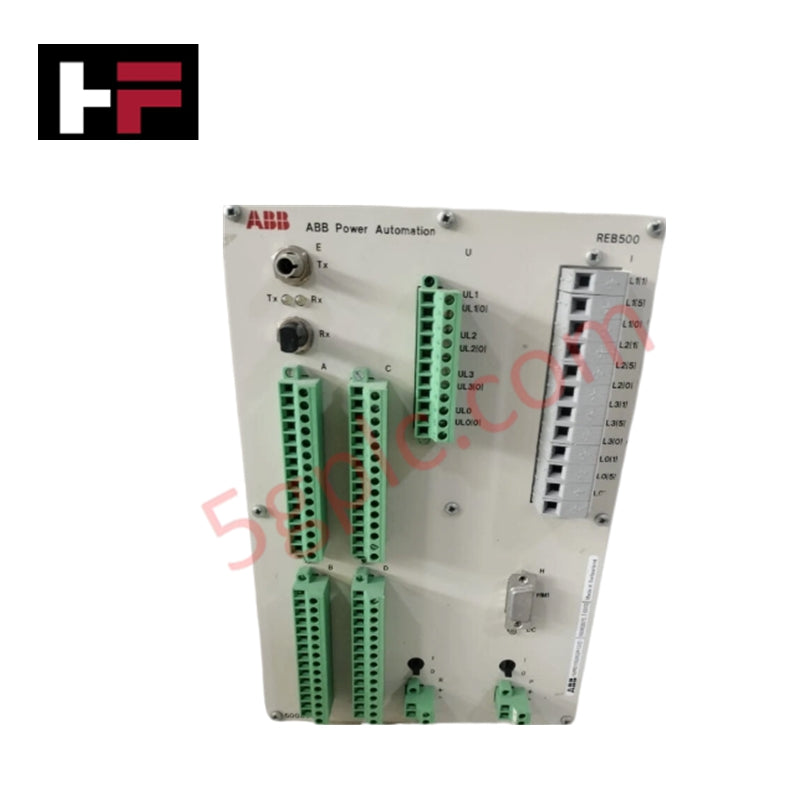

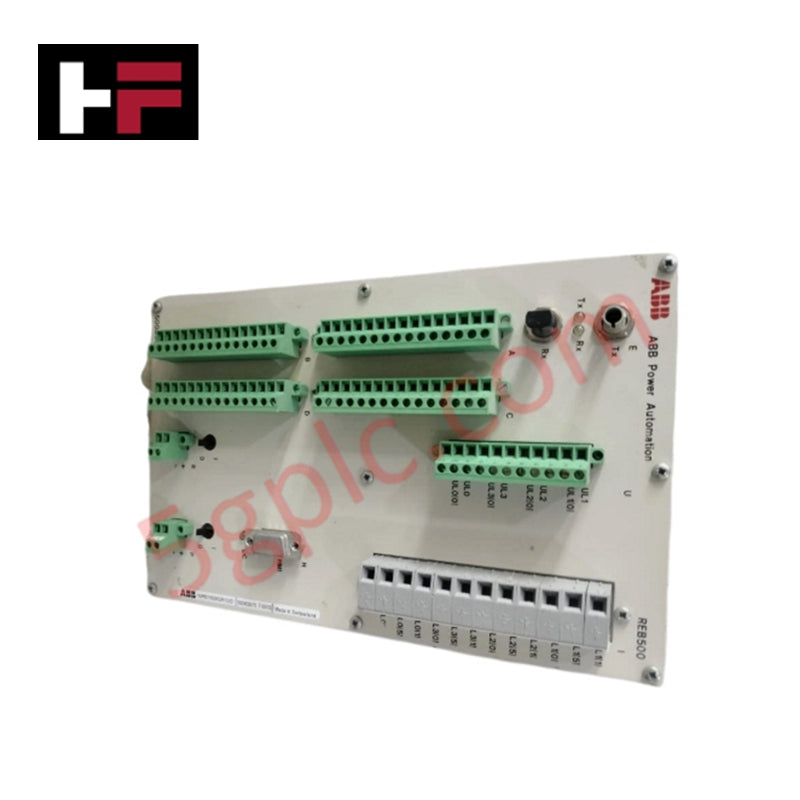

Product Details

Description

The ABB TU849 is a redundant Module Termination Unit (MTU) for the S800 I/O system, designed for intrinsically safe modules. It supports two I/O modules, providing full hardware redundancy and continuous operation in hazardous areas. The unit handles power distribution and signal routing, ensuring high availability and safe maintenance in chemical, oil, and gas applications.

Specifications

-

Manufacturer: ABB

-

Model Number: TU849

-

Order Number: 3BSE042560R1

-

Product Type: Redundant Module Termination Unit

-

Configuration: Supports 2 I/O Modules

-

Channel Capacity: Up to 16 channels (8 per module)

-

Application: Designed for Intrinsically Safe (IS) I/O modules

-

Rated Voltage: 50V DC

-

Mounting: Horizontal DIN Rail

-

Weight: 0.58 kg

-

Terminal Type: Screw terminals for field connections

Features

-

Redundant Reliability: Designed to host dual modules, ensuring that a single hardware fault does not result in a loss of process data or control.

-

Hazardous Area Integration: Optimized to maintain the electrical integrity required for intrinsically safe I/O loops when paired with compatible IS modules.

-

Hot-Swappable Design: Enables the extraction and replacement of one module while the partner unit continues to manage live process variables.

-

Mechanical Security: Built-in keying mechanisms prevent the accidental insertion of non-compatible modules, safeguarding the field circuit and hardware.

-

Clear Signal Routing: Organized terminal layout simplifies the wiring of complex 8-channel loops, reducing the risk of installation errors during commissioning.

-

Robust Construction: Passive backplane architecture ensures long-term stability in demanding industrial environments with minimal maintenance requirements.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.