Product Details

Description

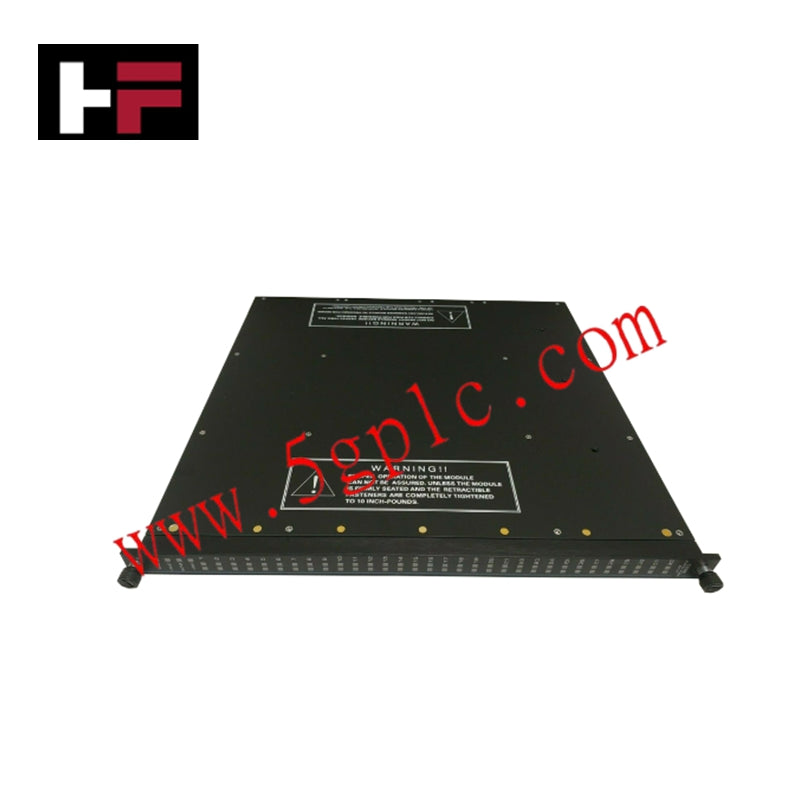

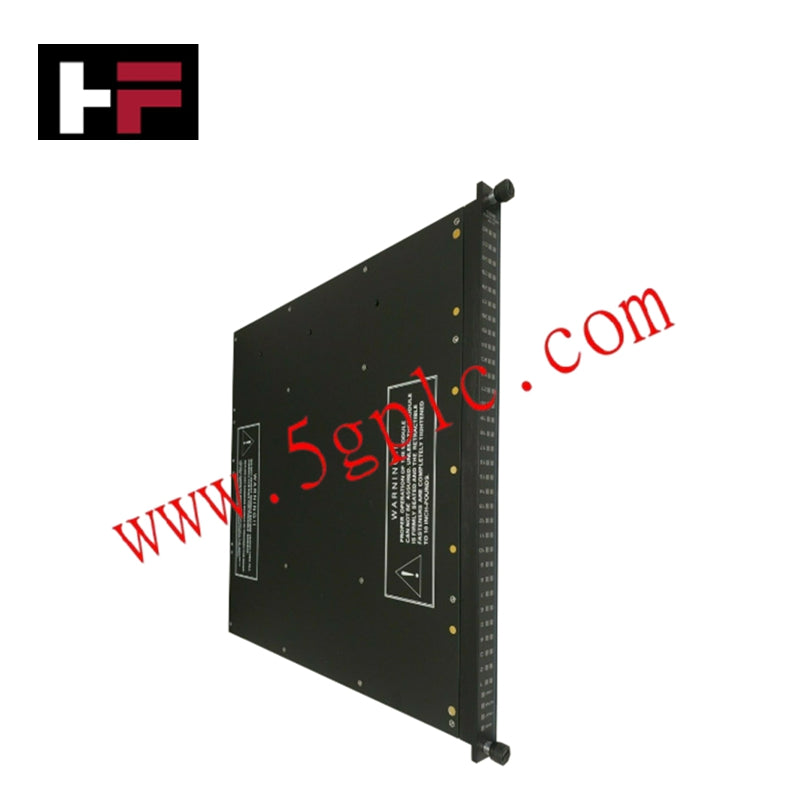

The Triconex 1600071-001 is a specialized Trisen TurboSentry controller module designed for the comprehensive monitoring and protection of critical rotating equipment. It provides real-time vibration analysis and automated safety shutdown capabilities for turbines, compressors, and pumps in high-demand industrial environments.

Specifications

-

Manufacturer: Schneider Electric (Triconex).

-

Country of Origin: USA.

-

Model Number: 1600071-001.

-

Input Voltage: 24 VDC nominal.

-

Number of I/O Points: 164 points for high-density monitoring.

-

Physical Weight: Approximately 2.1 kg (4.7 lbs).

-

Dimensions: 16.0" x 3.0" x 6.0" (406 mm x 76 mm x 152 mm).

-

Operating Temperature: -40°C to +70°C.

-

Storage Temperature: -40°C to +85°C.

-

Humidity Range: 5% to 95% non-condensing.

Features

-

Vibration Monitoring: Provides advanced detection of mechanical anomalies in turbomachinery to prevent catastrophic equipment failure.

-

High-Density Configuration: Supports a large number of digital and analog input signals within a compact modular footprint.

-

Real-Time Data Processing: Delivers high-speed analysis of rotating equipment health to enable proactive maintenance and informed decision-making.

-

Fault-Tolerant Architecture: Integrated into the Triconex safety environment to ensure maximum uptime and system reliability.

-

Advanced Diagnostics: Includes built-in self-testing and LED indicators to monitor the integrity of input signals and internal hardware status.

-

Environmental Hardening: Built to operate reliably in extreme temperature ranges and harsh industrial processing conditions.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.