In modern industrial automation, reliable communication between remote I/O and PLCs is essential. The Schneider Electric CRA module enables efficient Ethernet-based remote I/O connectivity in PLC and DCS systems, improving scalability, diagnostics, and overall networked automation performance.

Product Details

Overview

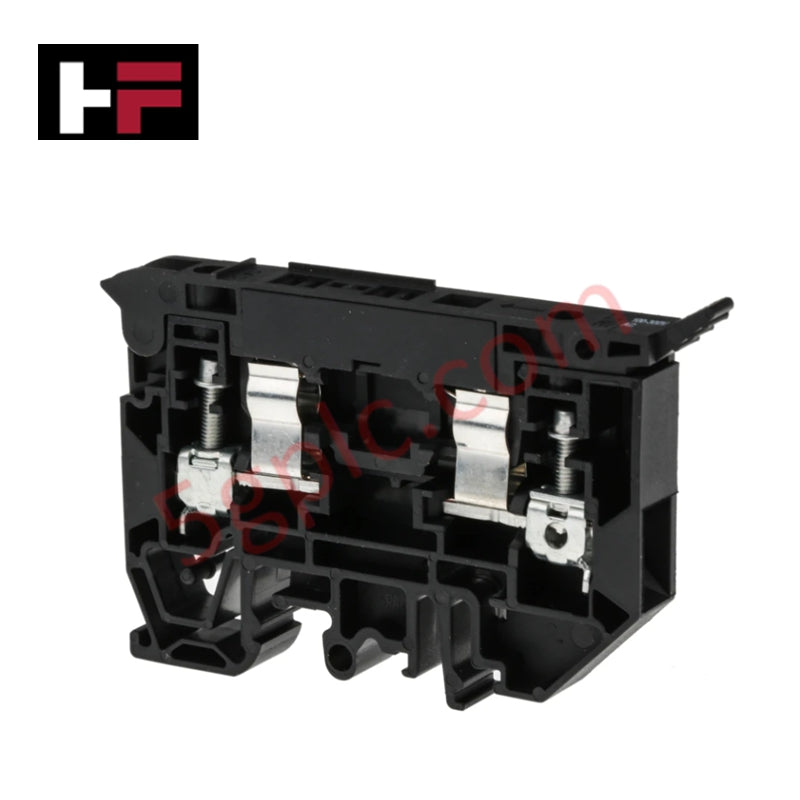

The 1492-H5 (1492-H5) is a high-density, rail-mounted fuse terminal block designed for the 1492 Finger-Safe wiring system. This single-pole component provides essential circuit protection for control-level signals. It features an integrated blown-fuse indicator to accelerate troubleshooting by providing a clear visual signal when a circuit interruption occurs. Engineered with a compact footprint, it ensures high-density wiring efficiency while maintaining strict safety standards for electrical contact prevention.

Detailed Technical Specifications

-

Terminal Type: Finger-Safe Fuse Block

-

Termination Method: Precision Screw Connection

-

Visual Diagnostics: Integrated Red LED Blown Fuse Indicator

-

Operating Voltage Range: 10–57V AC/DC

-

Maximum Current Capacity: 15 Amps

-

Wire Stripping Range: AWG 30 to AWG 10 (0.05 – 4.0 mm²)

-

Pole Configuration: 1-Pole (Single Circuit)

-

Housing Material: Thermoplastic (Black)

-

Mounting Compatibility: 35mm DIN Rail

-

Connection Torque: 0.8 N·m (7 lb·in)

-

Dimensions: Standard 1492-H Series width for high-density spacing

-

Operating Temperature: -40°C to +105°C (-40°F to +221°F)

Application and Maintenance

The 1492-H5 (1492-H5) is primarily used in control panels for protecting PLC I/O points, solenoid valves, and sensor loops. The finger-safe design minimizes the risk of accidental contact with live energized parts, making it ideal for high-traffic industrial enclosures. The screw-clamp mechanism is optimized for high vibration resistance, ensuring long-term connection integrity in demanding environments such as motor control centers and distributed I/O stations.

Engineering FAQ

-

What type of fuse is compatible with this holder?The 1492-H5 (1492-H5) typically accepts standard 1/4 inch x 1-1/4 inch (6.3 x 32 mm) fuses. Always verify the specific fuse dimensions against the holder clip tension.

-

Does the LED indicator require a separate power source?No, the leakage current through the LED circuit across the blown fuse provides the illumination. Note that a small amount of leakage current (typically <2mA) will exist when the fuse is blown.

-

Is this block compatible with standard 1492-H jumpers?Yes, it integrates with the standard 1492 series jumper system, allowing for efficient commoning of power or ground across multiple adjacent blocks.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.

Tech & Buying Guide

Technical Insights, Installation Guides, and Buying Tips