In modern industrial automation, reliable communication between remote I/O and PLCs is essential. The Schneider Electric CRA module enables efficient Ethernet-based remote I/O connectivity in PLC and DCS systems, improving scalability, diagnostics, and overall networked automation performance.

Product Details

Overview

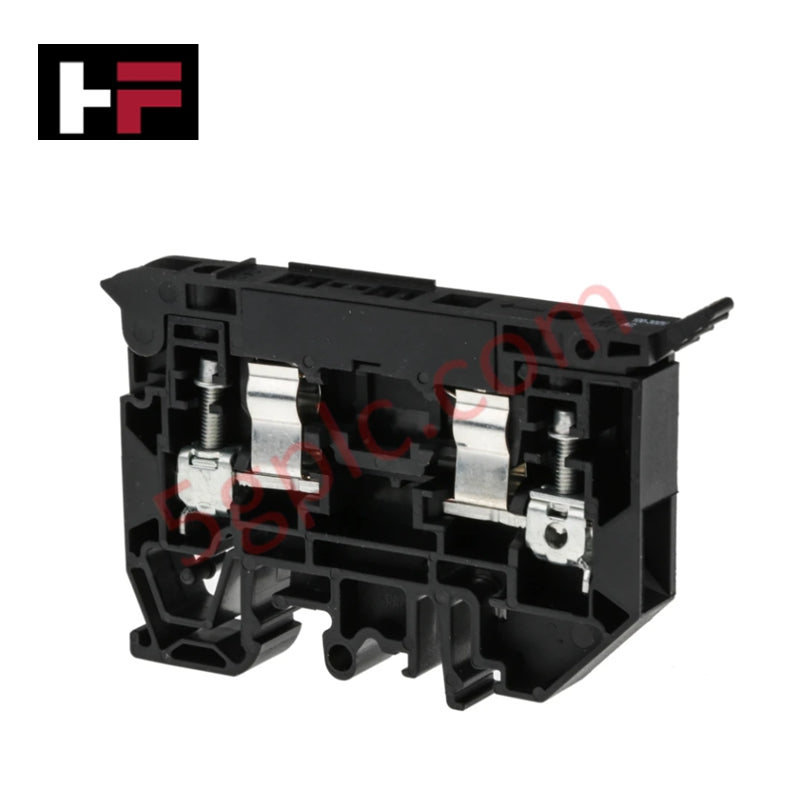

The 1492-H4 (1492-H4) is a high-density, rail-mounted terminal block from the 1492 Series designed for circuit protection in AC-powered control systems. This single-pole component features a robust screw-clamp mechanism for secure wire termination and an integrated neon indicator for rapid identification of blown fuses. Its slim 9.1mm width allows for significant space savings in crowded electrical enclosures, providing both a disconnect point and circuit protection in a unified footprint.

Detailed Technical Specifications

-

Connection Interface: Precision Screw Terminal

-

Circuit Protection: 1-Pole Fusible Block

-

Voltage Rating: 300V AC

-

Maximum Current: 15 Amps

-

Visual Diagnostic: Integrated Neon Blown Fuse Indicator (typically for 120V-240V AC applications)

-

Conductor Capacity: Up to 4 mm² (compatible with AWG 30 to AWG 10)

-

Housing Color: Black Industrial Thermoplastic

-

Unit Dimensions: 1.85 in Length x 3.2 in Width x 0.36 in Height (47 x 81.3 x 9.1 mm)

-

Mounting Method: 35mm DIN Rail compatibility

-

Weight: 0.05 lbs (Approx. 22.7 grams)

-

Series Compatibility: Allen-Bradley 1492 Finger-Safe Wiring System

Practical Deployment and Maintenance

The 1492-H4 (1492-H4) is optimized for high-voltage AC control loops where visual status feedback is required for maintenance personnel. Unlike LED indicators which are common in low-voltage DC circuits, the neon lamp in the 1492-H4 (1492-H4) is engineered to handle higher AC potentials safely. The screw-clamp design ensures gas-tight connections that resist loosening in high-vibration environments, such as motor control centers or specialized machinery panels.

Engineering FAQ

-

What is the main difference between the 1492-H4 and 1492-H5?The 1492-H4 (1492-H4) utilizes a neon indicator suitable for higher AC voltages (300V), whereas the H5 variant typically uses a low-voltage DC LED indicator (10-57V). Always match the indicator type to your control circuit voltage.

-

Does this block include the fuse?Fuses are typically sold separately to allow users to select the specific amperage rating required for their branch circuit protection.

-

Can the neon indicator be replaced if it fails?No, the indicator is integrated into the housing. However, neon lamps are selected for their exceptionally long service life in industrial conditions.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.

Tech & Buying Guide

Technical Insights, Installation Guides, and Buying Tips